NEW ultra-performant & eco-friendly plastic painting lines

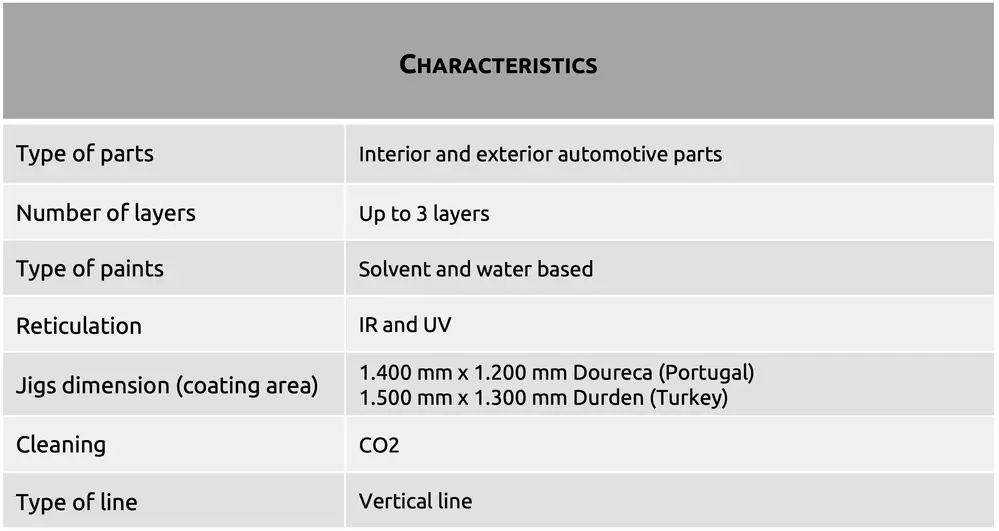

We paint the plastic parts of our most demanding customers: mirror housings, monograms, interior and exterior door trims, … with an environmentally friendly orientated process.

Both water base and solvent base paints are possible as well as UV cure.

Painting plastic parts is a process which is not only necessary for improving the aesthetics of the plastic parts, but it also offers numerous benefits for the automotive industry as a whole. One of the many challenges of that process is the ecological one. At Dourdin SAS we are offering two brand new 3 layers robotized lines not only the best end results but with an environmentally friendly orientated process.

One of the main benefits of industrial painting is the ability to enhance the appearance of the finished product. Paint can be applied in a variety of colours and finishes, such as matte, gloss, or metallic, to give the plastic parts a more attractive and professional look.

This is especially important for car manufacturers for example, who rely on the visual appeal of their products to attract customers.

We offer a variety of finishes that will unleash your creativity and design projects. Here are just a couple of examples:

In addition to improving aesthetics, industrial painting also offers protection for plastic parts. Paint acts as a barrier against environmental factors such as UV radiation, water, and dirt, which can cause plastic parts to degrade over time.

We offer several techniques on our two brand new painting lines such as paint over Trivalent & Free Chrome, laser etching, pad printing and hot stamping over paint, …

When working with us, we guide you also to overcome some challenges like the compatibility of paint with plastic. Some plastic materials are less suitable for painting due to their chemical properties, which can cause the paint to peel or crack after drying. By involving us at an earlier stage in your project we can help you choose the right type of paint and plastic material to ensure a long-lasting and durable finish.

In order to achieve the best results, we are very careful in the preparation of the plastic surface before painting. This involves cleaning the plastic surface to remove dirt, oil, and other contaminants.

Our rigorous processes, planning and attention to details will deliver the perfect high-quality finish for all your plastic parts: mirror housings, monograms, interior and exterior door trims, steering wheel covers, front grilles, ….

In line with our commitment to the planet we have developed our new painting lines with an environmentally friendly approach.

As you might know, painting plastic parts also presents some ecological challenges such as the proper disposal of paint waste but the main ecological challenge is the release of volatile organic compounds (VOCs) during the painting process. VOCs are gases emitted by certain materials and can have negative impacts on air quality and human health.

To minimize the release of VOCs, we have integrated RTO, Regenerative Thermal Oxidizer, which gives us a 99.8% destruction efficiency and meet the world’s most stringent emission codes for VOC reduction.

We also use a ceramic cleaning process to remove easily organic deposits, without smoke emission to meet broader worldwide environmental codes.

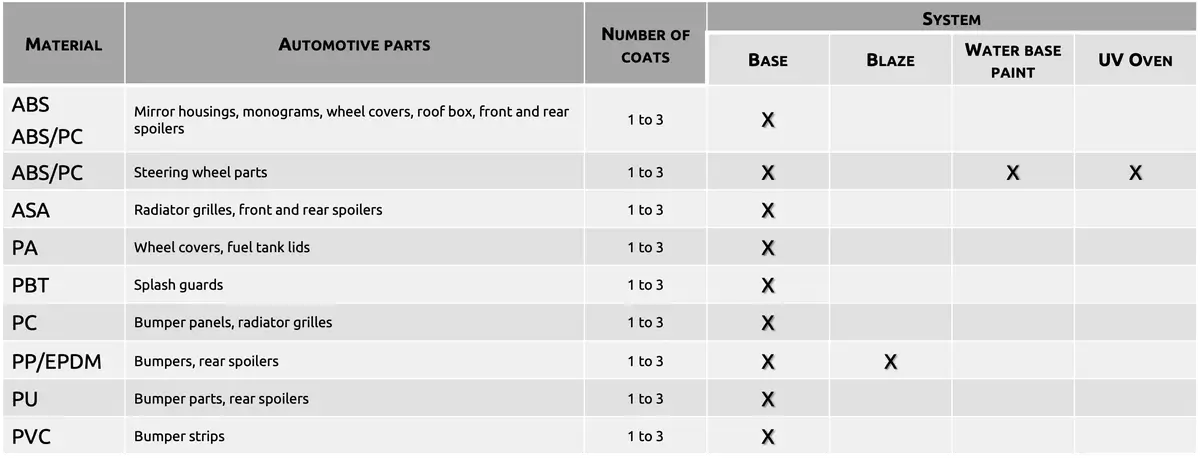

Here is an overview of parts we can handle for the automotive industry and the processes for each depending on the material, the dimension and the usage of the part:

You have a project, in the automotive industry or outside, and you are looking for a solution? Don’t hesitate to challenge us; we can partner with you, tag along to give you the best solution for your project.

Share this article